Collaborative projects

FoodSafeBioPack (2021-2025)

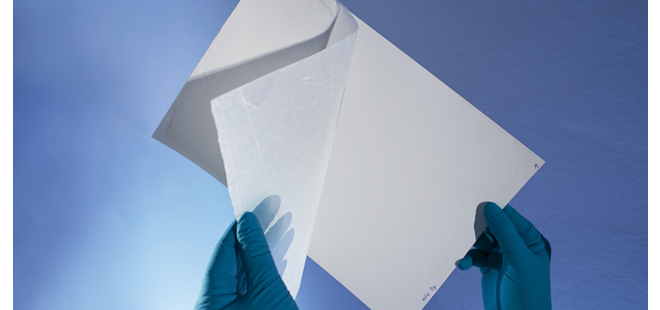

Assessing and managing the migration of contaminants from cellulose packaging

- Obtaining a multi-scale description of the transfer problem of contaminants

- Characterising the properties of a universal functional barrier based on cellulose microfibrils (CFMs)

EcoFreshChain (2021-2025)

Eco-design of Fruit and Vegetable Packaging and Post-Harvest Cold Chain

- Reduce post-harvest losses of fresh fruits and vegetables up to the consumer, which can reach 38% of the total volume produced (Wu and Defraeye, 2018).

- Take into account the very short shelf life and high perishability of fresh fruits and vegetables.

- Prevent post-harvest food waste in the logistics chain and at the consumer level, which remains a major issue in France (Ademe, 2016), Europe, and worldwide (FAO, 2013).

FIBERBOND (2024-2028)

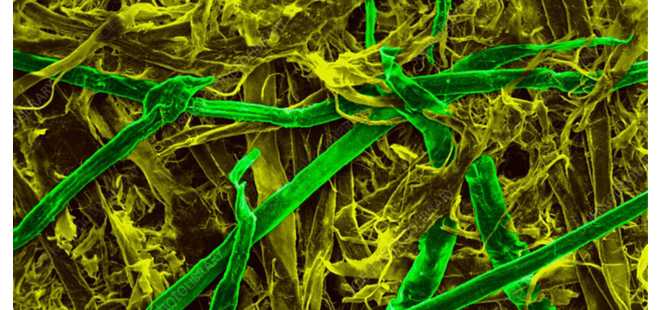

Cellulosic fibre mats with improved fibre bonds towards lighter, stronger and stretchable bio-based material

The aim of the FiberBond project is to significantly improve the strength and deformation at break of wet-formed cellulose fibre mats, in order to reduce the consumption of materials, water and energy, and to give them new 3D formability properties.

REGENCELL (2023-2026)

Clean process for dissolving wood cellulose to produce textile yarns

The RegenCell project is supported by the French National Research Agency (ANR), coordinated by the LGP2 laboratory and also involving the CTP, the UniLaSalle Polytechnic Institute and the Gemtex laboratory. Its aim is to develop a new textile production process based on wood cellulose, as an ecological and cost-effective alternative to the current viscose process.

Industrial development of Chromatogeny

A technology currently being deployed

- Accelerate the industrialization of Chromatogeny

- Develop a pool of machines in France and Europe to meet the needs of targeted markets (food & non-food)

- Support industrials in the transfer of Chromatogeny technology

IonMCell (2024-2027)

High performance functionalized cellulose membranes for Fuel Cell

The aim of the IonMcell project (ANR) is to produce proton exchange membranes for fuel cells (PEMFC) based on cellulose materials. The short-term aim is to replace the polyfluoroalkylated substances (PFAS) used in commercial membranes such as Nafion or Aquivion.

REBIOLUTION (2023-2026)

Novel biodegradable, REcyclable, BIO-based and safe plastics with enhanced circuLar properties for food packaging and agricUltural applicaTIONs

- Design and synthesis of fully bio-based polyester for paper food packaging and agricultural mulch film

- Raw material sourcing from annually renewable resources

- Biodegradable in home and industrial composting, soil and aquatic environments

- Recyclable

CORNERSTONE (2024-2027)

Combined technologies for water, energy and solute recovery

- Developing new technologies from lab to pilot scale to treat industrial waters

- Reusing treated waters and recovered solute to decrease water withdraws and raw material consumption

- Testing smart monitoring tools for the digitalization and intensification of industrial processes

- Developing decision support tools for digitally enabled industrial water, energy and resources stewardship

FIMP (2023-2024)

Functionalizing by Printing

- Focusion work on sustainable development and eco-design via printable solutions to replace plastic on recyclable single-material bases

- Proposing a support programme for all players in the Hauts-de-France region

- Positioning / repositioning local players in the future regional industries such as electric vehicles

BIONANOPOLYS (2021–2024)

Creating a network to speed up the development of bio-based materials

- Creating a European network of pilot lines and associated services (OITB: Open Innovation Test Bed)

- Setting up a single entry point and a dedicated platform

- Developing and optimising the pilot lines

- Validating the proposed service portfolio through several industrial case studies in various sectors such as packaging, non-woven materials, bioplastics, cosmetics and textiles.

Citeo-CTP partnership (2022-2028)

Six years to unleash the full potential of paper and board!

Paper and board is renewable and recyclable, and has yet to reveal all its strengths. Given the pressing need to reduce environmental impacts, there is still room for improvement. Building on the past six years of collaboration and innovation in paper and paper/board packaging, Citeo and the Centre Technique du Papier (CTP) have just renewed their partnership. With one key aim: developing their innovative solutions at an industrial scale to make them available to companies in tangible ways, and hence meet the expectations of consumers.

CelluWiz (2019-2022)

Process developments to obtain 100% cellulosic packaging material, barrier, recyclable and compostable

- Develop two technologies: chromatogeny and wet lamination of MFC

- Produce a fully cellulosic multilayer packaging that is recyclable and compostable

- Provide an alternative to the plastic-based multilayers in packaging

ULTRACELL (2018-2020)

Ultrasonic welding of paper and nanocellulose

Development of an ultrasonic paper and board welding process making it possible to :

- Eliminate glue and the associated food contact problems for paper and board packaging,

- Guarantee a sharp reduction in the costs related to packaging recycling, and the absence of mineral oils or other contaminants,

- Achieve performance levels comparable to those of adhesive-based assemblies in terms of adhesion quality, energy cost and production rate.

SpotView (2016-2020)

Sustainable Processes and Optimized Technologies for Industrially Efficient Water Usage

The 3 main objectives of the SPOTVIEW project were:

- to develop and demonstrate innovative, sustainable and efficient techniques,

- to optimize the use of natural resources, especially water, in three industrial sectors (Dairy, Pulp and Paper and Steel),

- to assess a total of 14 existing and new separation and treatment technologies at pilot scale.

Sherpack (2017-2020)

A sustainable, recyclable, and biodegradable high barrier flexible packaging material

- Produce two proofs of concept for an innovative food packaging material that is compatible with a circular

economy

- Develop the three breakthrough technologies required in order to produce this material

E-BLISS

An innovative blister, recyclable and biodegradable

- To anticipate the French Law against waste and for Circular Economy (AGEC) which bans the use of plastic films for delivery of printed documents (newspapers, magazines, advertisements, etc.) from 2022.

- To create a transparent paper to replace plastic blister packs for magazines and newspapers.

- To support the implementation and production of this new innovative cellulose packaging