BIONANOPOLYS (2021–2024)

Creating a network to speed up the development of bio-based materials

- Creating a European network of pilot lines and associated services (OITB: Open Innovation Test Bed)

- Setting up a single entry point and a dedicated platform

- Developing and optimising the pilot lines

- Validating the proposed service portfolio through several industrial case studies in various sectors such as packaging, non-woven materials, bioplastics, cosmetics and textiles.

Aim of the project

With a view to phasing out fossil-based materials, the Bionanopolys project aims to create a network of pilot lines and associated services to speed up the route to market for bio-based nanomaterials.

The four-year project will involve setting up this network with several European partners, optimising the pilot lines and defining the services to be proposed.

Once maturity level TRL 7 has been reached, these pilot lines and their various associated services will be tested in industrial conditions for various sectors such as packaging, non-woven materials, bioplastics, cosmetics and textiles.

On completion of the project, the dedicated platform and the single entry point created will provide companies with easier access to a wide variety of services to develop their new bio-based products.

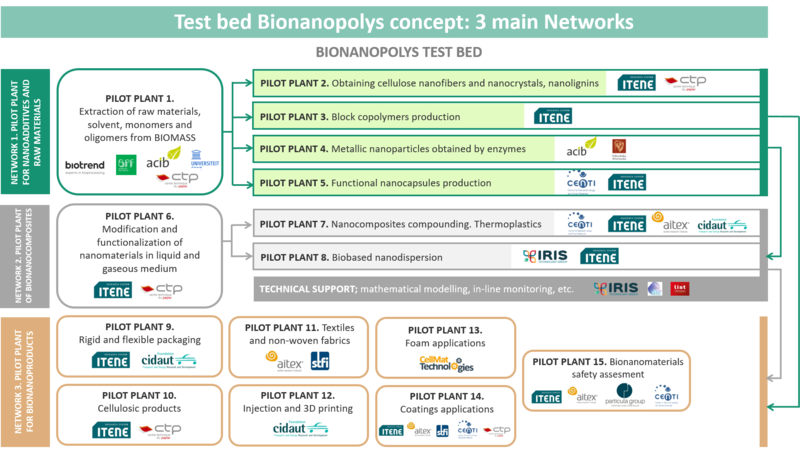

The Bionanopolys OITB is composed of three groups of pilot lines:

-

The first group comprises the pilot lines involved in extracting raw materials from biomass and producing nanoadditives (cellulose nanocrystals and microfibrils, nanolignin, block copolymers, metallic nanoparticles and functional nanocapsules). The CTP is working on extracting cellulose from woodchips and annual plants using cooking and bleaching pilots. At the same time, it is optimising the twin-screw extrusion process in order to produce high-concentration MFCs (microfibrillated cellulose).

-

The second group comprises the pilot lines involved in the functionalisation of bionanomaterials and the production of bionanocomposites. The CTP is using its chromatogeny pilot to give various cellulose substrates water and water vapour barrier properties.

-

The third group comprises the pilot lines involved in producing bionanoproducts based on bionanoaddives and bionanocomposites for various applications such as stiff and flexible packaging, textile and non-woven materials, foams, and cellulose products. The CTP is working on producing MFC films, depositing MFCs on 3D cellulose objects to give them grease and oxygen barrier properties, and applying coatings with functional nanoadditives.