Commercial printing trials, full-scale testing

Evaluating and characterising the printability of any substrate (paper, board…)

- Evaluate a product intended for printing by testing it on industrial equipment

- Perform a retest in the context of a claimunder industrial conditions

- Study printing quality and defects on all types of substrtes, paper, board, ink, etc.

- Perform annual competitive benchmarking for papermakers, converters, printers or suppliers to these industries

Generate Value...

Substandard paper and board printing quality can give rise to claims and significant financial losses for a paper mill. Moreover, when new printing substrates are developed; they need to be evaluated in true conditions in order to guarantee their success once they are put on the market. Performing benchmark tests on competitors’ products is also a means of maintaining a strong market position.

Thanks to a network of printers and more than 40 years of experience in the field, the CTP has the capability to use industrial presses to evaluate and assess the printability of all your printing substrates as paper & boards:

- on different markets (newspaper, magazine, office paper, folding boxboard for packaging, corrugated box, art book, security, etc.),

- on different types of substrates (coated or uncoated, boards, speciality papers),

- and nearly all existing printing processes (sheet-Fed and web offset, rotogravure, flexography, electrophotography, inkjet, screen, etc.).

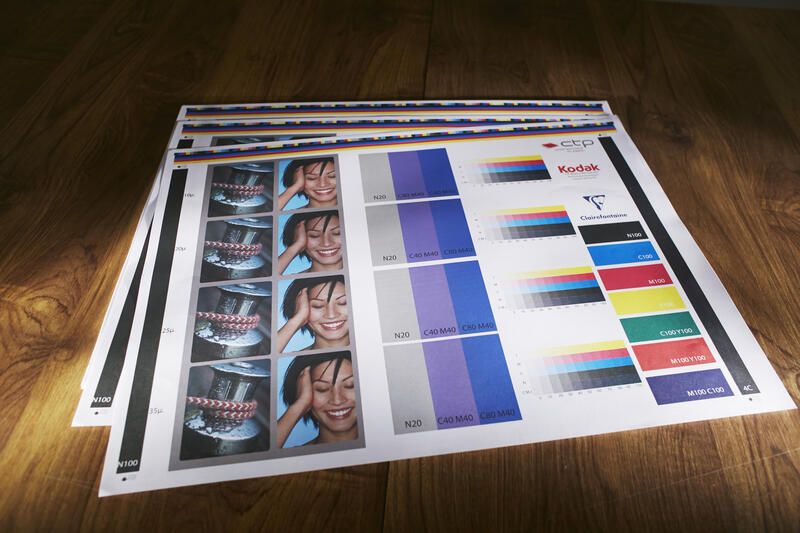

Test forms suited to each situation

Contexte et réalisation

Printability, print quality and runnability of papers and boards are important criteria used by printers and publishers to evaluate and assess products. The CTP has all the resources required to provide answers in this regard, concerning printing substrates and processes of all types.

The right inks for each type of paper

Content of services

- Precise analysis of the requirement of the requesting party, which may be a papermaker, a publisher, an ink manufacturer or a printer.

- Selection of the printing test form to be used and printing protocols tailored to each specific feature.

- Organisation and implementation of all services:

* Rental of machines from a partner printers with a guarantee of confidentiality,

* Supply of materials,

* Fabrication of printing forms. - Monitoring of the printing process at the printshop and extraction of suitable samples for the situation.

- Characterisation and analyses of the printed materials with a tried and tested methodology.

Characterisation zones on the test forms

Delivrables

- Dispatch of representative samples to the requesting party.

- Formalisation of a detailed report on the printing trials and analyses, and characterisation of the printed materials.

- Comments and analyses on overall printingquality.

- Precise comparison of the various papers tested.