Innovation

Collaborative projects

CORNERSTONE (2024-2027)

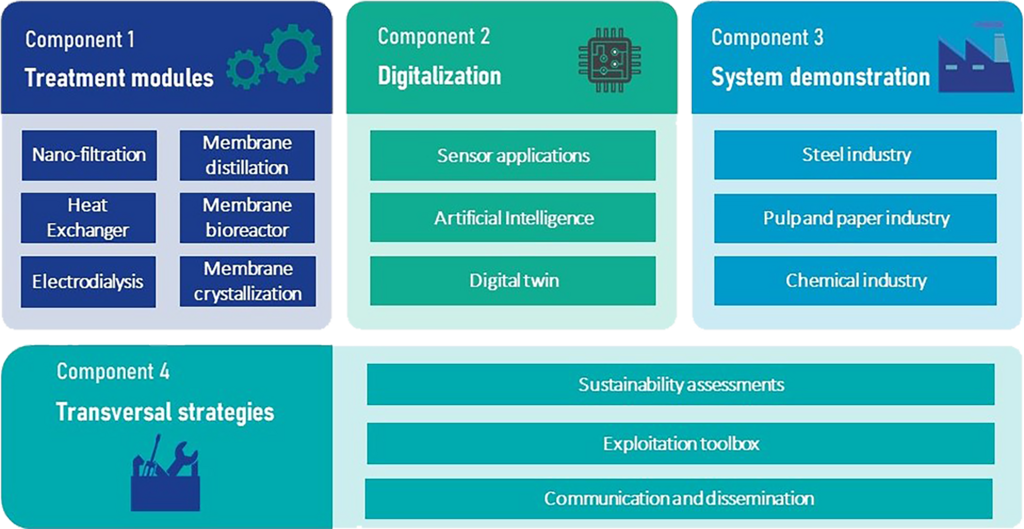

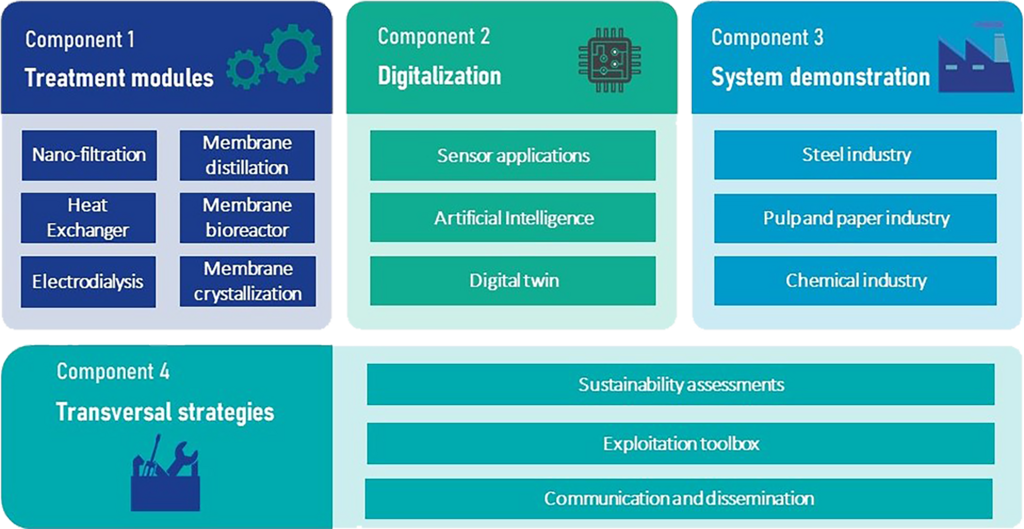

Combined technologies for water, energy and solute recovery

- Developing new technologies from lab to pilot scale to treat industrial waters

- Reusing treated waters and recovered solute to decrease water withdraws and raw material consumption

- Testing smart monitoring tools for the digitalization and intensification of industrial processes

- Developing decision support tools for digitally enabled industrial water, energy and resources stewardship

Aim of the project

The CORNERSTONE consortium wants to achieve long-term circular economy of EU industry via recycling and reusing resources from industrial water and wastewater streams by developing novel technologies in combination with existing processes - combined with smat monitoring technologies and digital tools for risk and decision management.Via novel technologies the aim is to enable up to 90% wastewater, energy and solute reuse by tapping the potential of currently difficult-to-treat wastewater streams and using waste heat for water recovery. These new developments, together with digital tools shall be easily deployed cross-sectorial.

Targeting steel, pulp & paper, and chemical industries, CORNERSTONE aligns with P4Planet’s objectives, paving the way for circular processes and EU climate neutrality by 2050.

Traditional industrial wastewater practices fall short in achieving water valorization and reuse— a misalignment with the ambitious goals set by Europe. The recently launched CORNERSTONE project sets the goal of bridging this gap by integrating cutting-edge technology and digital solutions into established industrial wastewater treatment systems. The project not only aims to facilitate the recovery of freshwater, energy, and solutes but also to modernize wastewater treatment systems that seamlessly align with the principles of the circular economy.

The CORNERSTONE systems integration plan for typical recycled fibre (RCF) industrial effluents includes four key technologies:

(a) Non-clogging heat exchangers (Module 1),

(b) Hollow fiber nanofiltration (HF-NF) for selective removal of ions and organic matter (Module 3),

(c) Bipolar electrodialysis (BMED) for converting permeate to acid and base (Module 5), and

(d) Membrane crystallization (MCr) for removing inorganic substances as a solid by-product (Module 6).

The integrated process involves pre-treatment, pH control, and filtration through an HF-NF membrane unit, followed

by BMED and MCr stages. Recovered thermal energy is utilized in MCr by preheating the NF concentrate. The goal is to optimize conditions for efficient continuous operation while promoting sustainable water, energy, and material recovery.

Added value for society:

The CORNERSTONE systems integration plan for typical recycled fibre (RCF) industrial effluents includes four key technologies:

(a) Non-clogging heat exchangers (Module 1),

(b) Hollow fiber nanofiltration (HF-NF) for selective removal of ions and organic matter (Module 3),

(c) Bipolar electrodialysis (BMED) for converting permeate to acid and base (Module 5), and

(d) Membrane crystallization (MCr) for removing inorganic substances as a solid by-product (Module 6).

The integrated process involves pre-treatment, pH control, and filtration through an HF-NF membrane unit, followed

by BMED and MCr stages. Recovered thermal energy is utilized in MCr by preheating the NF concentrate. The goal is to optimize conditions for efficient continuous operation while promoting sustainable water, energy, and material recovery.

Added value for society:

- Minimization of freswater consumption though the drastic reduction of the industry's water footprint.

- Recovery of valuable materials to produce new products (NaOH, HCI, CaSO4) for industrial use in the spirit of the circular economy.

- Zero liquid discharge and protection of the environment.

- Sustainable development of the P&P industry and creation of new green jobs.