Innovation

Collaborative projects

EcoFreshChain (2021-2025)

Eco-design of Fruit and Vegetable Packaging and Post-Harvest Cold Chain

- Reduce post-harvest losses of fresh fruits and vegetables up to the consumer, which can reach 38% of the total volume produced (Wu and Defraeye, 2018).

- Take into account the very short shelf life and high perishability of fresh fruits and vegetables.

- Prevent post-harvest food waste in the logistics chain and at the consumer level, which remains a major issue in France (Ademe, 2016), Europe, and worldwide (FAO, 2013).

Aim of the project

The aim is to design a new biodegradable cellulose-based packaging and combine it with refrigeration to preserve fruits and vegetables along the post-harvest chain until consumption.A multi-criteria analysis approach (quality, logistics cost, environmental impact) is developed to quantitatively assess the performance of the post-harvest chain using new packaging compared to conventional packaging.

Two types of packaging are studied :

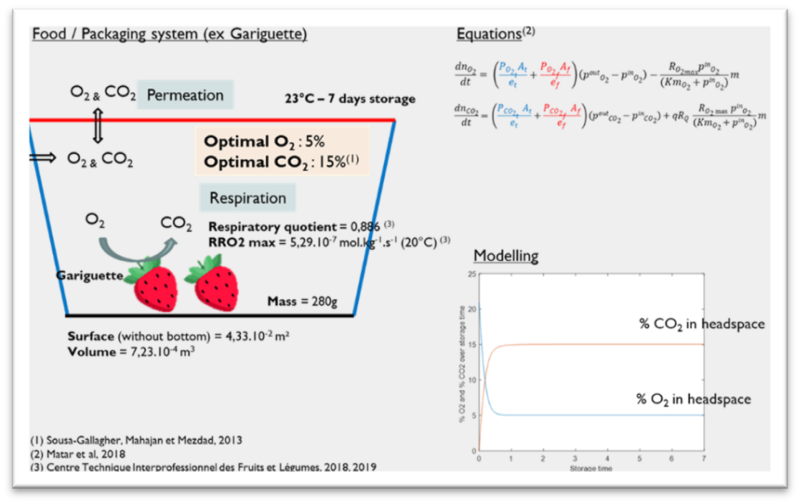

- Modified Atmosphere Packaging (MAP) trays for strawberries in long supply chains.

- Interleaving film above the packages for salads in local supply chains.

ECOFRESHCHAIN is an ANR project led by INRAE (Frise) and several partners*, aiming to improve the distribution chain of fruits and vegetables, particularly strawberries and salads. It includes a study of consumer behaviour, carried out through a questionnaire and observations, to analyse preferences related to purchasing, packaging, and storage conditions of the products. Interviews were also conducted with professionals to better understand logistical and preservation constraints.

A major innovation of the project is the development of a cellulose-based packaging for product preservation. The Paper Technical Centre (CTP) has created 250g trays made from barrier kraft cardboard, validated for food use. These packages optimise strawberry preservation through modified atmosphere packaging (MAP), which maintains favourable CO2 and O2 levels. Tests have shown a significant improvement in the shelf life of strawberries, both during transport and when consumed at home.

The experimentation also focused on optimising the cooling of products during transport. An experimental setup measured airspeed and identified the best conditions for strawberry preservation. A CFD (Computational Fluid Dynamics) model was used to validate these conditions and optimise cooling.

The project also assessed the impact of the new packaging on the logistics chain and costs by comparing the performance of the various links in the distribution chain. An environmental impact analysis showed that the cellulose-based packaging has a similar impact to current solutions, but with potential for improvement in resource reduction and energy consumption.

A major innovation of the project is the development of a cellulose-based packaging for product preservation. The Paper Technical Centre (CTP) has created 250g trays made from barrier kraft cardboard, validated for food use. These packages optimise strawberry preservation through modified atmosphere packaging (MAP), which maintains favourable CO2 and O2 levels. Tests have shown a significant improvement in the shelf life of strawberries, both during transport and when consumed at home.

The experimentation also focused on optimising the cooling of products during transport. An experimental setup measured airspeed and identified the best conditions for strawberry preservation. A CFD (Computational Fluid Dynamics) model was used to validate these conditions and optimise cooling.

The project also assessed the impact of the new packaging on the logistics chain and costs by comparing the performance of the various links in the distribution chain. An environmental impact analysis showed that the cellulose-based packaging has a similar impact to current solutions, but with potential for improvement in resource reduction and energy consumption.

|

|

Modelling Optimal Strawberry Preservation Conditions

|