Evaluation of paper dusting during printing

Determining the risk of dusting on printed papers

- Simulate dusting defects reliably and simply

- Compare dusting of several papers

- Validate product improvements before release to market

Generate Value...

Through different projects it has performed over the last few years, the CTP has built up expertise in the phenomenon referred to as surface dusting.

A reliable evaluation method performed under industrial printing conditions has been developed.

It provides a means of comparing the dusting of different papers, and thus of anticipating possible disputes with printer clients.

This method can be used to help resolve a claim regarding a problem with a batch or product, but also in the context of developing new products or improving existing ones.

Offset press used for the evaluation

Context and performance

Dusting is a defect that appears during offset printing, resulting from fine particles of paper being extracted by the blanket.

As printing progresses, these particles bind together on the blanket and a white deposit appears, leading to frequent machine stoppages, and in turn to manual cleaning on the press at the printers.

It is therefore a cumulative defect: it only appears after a certain number of copies. It is hence complex to evaluate, which is why there is no reliable predictive laboratory tool.

In light of this, the CTP has developed a semi-industrial method of evaluating dusting, using a commercial offset press. The procedure and conditions of this test have been optimised in order to limit paper consumption and evaluation time.

Thus, an evaluation consumes 6000 linear metres (or 10000 machine revolution) and a total of eight one-side papers can be tested in one day. This evaluation is always performed on a comparative basis, given the potential impact of the difficulty of maintaining stable printing conditions from one day to the next.

Example of dusting observed on a blanket at the end of the test

Content of services

The CTP can evaluate the intensity of paper dusting. It can also:

- Analyse samples of the deposits to identify them.

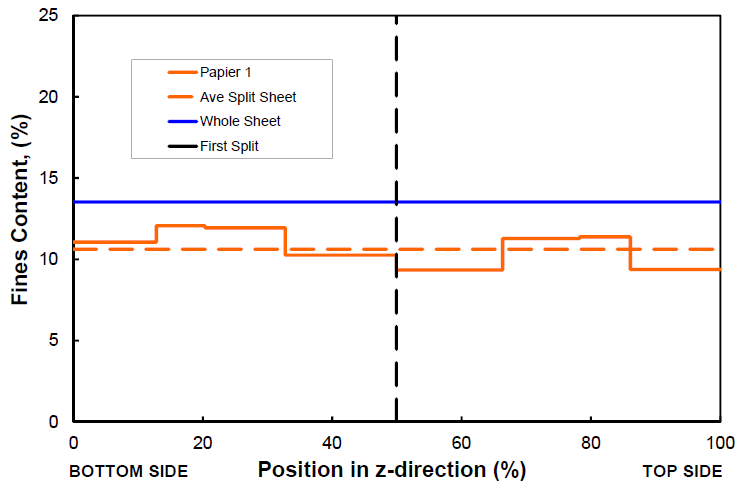

- Analyse papers in detail (average composition, ash content, fine elements content and distribution in the Z-direction depending on the sheet formation conditions, etc.) in order to target areas for improvement.