Foam generator

Lignocellulosic foams, deposits in foam

- Generation of foam in situ, within a particle suspension

- Continuous production of foam

- Wide range of variation in gas content of the foam, up to more than 90%

- Commercial system

The little story of the pilot

Production of foam materials based on cellulose is a concept that has gained momentum in the last few years.For example, many studies have demonstrated the excellent insulating properties of aerogels obtained by lyophilisation of a dispersion of microfibrils. Since this process is not easily transferable to an industrial scale, alternatives have been studied, such as generating a liquid foam by injecting air into a suspension of cellulosic particles, and then consolidating it into a solid foam by evaporating the water. This approach made it possible to achieve the target properties but only with mechanical agitation systems using a

batch process, in the laboratory.

Our rotor-stator system operates continuously and is already widely used in the food industry.

Characteristics

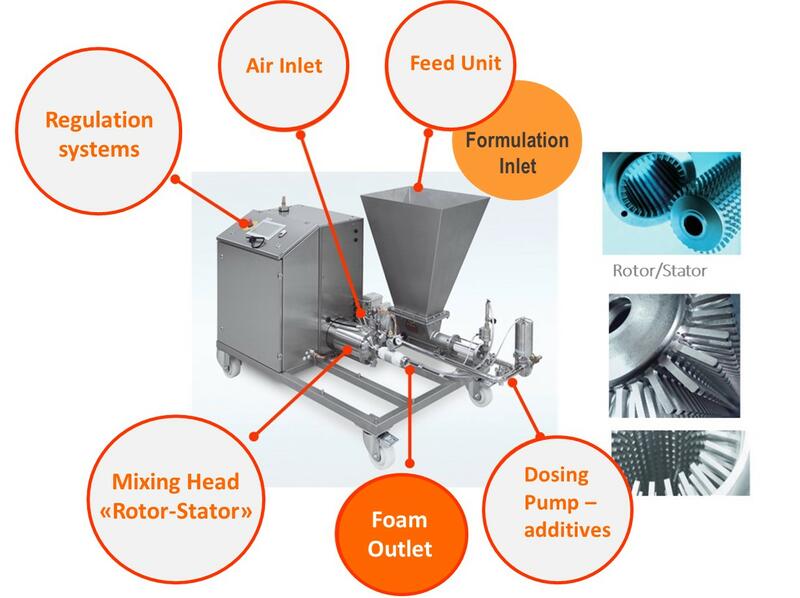

The compact system features:

- A supply unit with an integral pump

- A system for introducing additives using a metering pump

- A “rotor/stator” mixing head

- Measurement and control systems to adapt the injection of air in order to obtain the set final density of the foam

It is suitable for industrial applications (agri-food, textile, leather, adhesives, etc.) and laboratory applications.

A few figures...

- Rotor speed: up to 500 rpm

- Supply rate: up to 45 L/h

- Final foam density / aeration rate: 50-500 g/L / 60-95%

A few facts regarding its use...

The generator can be supplied with a wide variety of formulations containing particles of different sizes, fibres and foaming or stabilising agents.

The variable process parameters are the rotor speed, the supply rate (and in some cases the metering pump) and the final density of the foam, which is the instruction allowing the air flow rate to be adjusted to the value required to control the aeration rate.

The final properties of the resulting foam will come from a combination of the formulation and the process

parameters, which have strongly coupled effects and can be both complementary and antagonistic, and which therefore require an in-depth study for each raw material and each type of product to be developed (packaging foam, insulation, etc.).