Means

Laboratories

Laboratory for Fibres Analyses

Characterisation of lignocellulosic fibres from wood and annual plants

- To measure the dimensional and morphological characteristics of fibres

- To analyse statistically these characteristics

- To compare the fibrous elements of different biosourced materials

- To understand the impact of processes on lignocellulosic fibres

General informations

The characterisation of lignocellulosic fibres has been developed at CTP since the 90’s to better understand the production processes of pulps, papers and boards.Firstly, the laboratory was equipped with a PQM1000 fibres analyser, then replaced by the MorFi analyser, developed by CTP and Techpap teams.

Today, the laboratory has many fibres analysers, developed by CTP and/or its commercial subsidiary TechPap for a more accurate characterization of fibres, shives and fines present in pulps, papers and boards.

The analysis of morphological (flexibility, curl, weak points, fibrillation…) and dimensional (length, width, cell wall thickness…) characteristics of the components of lignocellulosic materials allows understanding the impact of processes from pulp to end product.

Context

With different automated analysers, the laboratory can accurately characterise the fibrous elements in a biosourced material, if it can be disintegrated to liberate all the elements to analyse.

Equipments

The available equipements in the laboratory are:

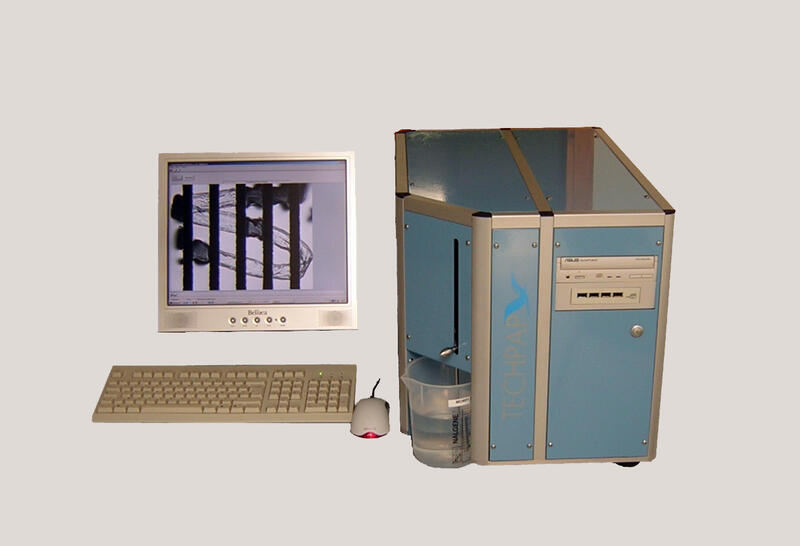

- Analyser MorFi Lab

- Analyser MorFi Great Channel

- Analyser MorFi Néo

- Analyser FibreFlex

- Analyser MorFi CWT

The obtained analysis allows obtaining mean values of the main morphological and dimensional characteristics of fibres, shives and fines (elements with a length < 200 µm) and the associated distribution in 10 classes.

It is also possible to analyse the residual fibrous elements contained in microfibrillated cellulose gels.

The FibreFlex analyser allows measuring the wet flexibility of fibres, their conformability and their degree of external fibrillation.

The MorFi CWT analyser allows measuring the cell wall thickness of fibres.

All the paper pulp grades can be analysed: unbleached and bleached chemical pulps, unbleached and bleached mechanical pulps, recycled fibres and deinked pulps.

These analyses allow controlling the impact of processes on the fibrous elements characteristics.

|

|

|

||

| Analyser MorFi Néo | Analyser FibreFlex | Analyser MorFi Cell Wall Thickness (CWT) |