Dimensional variations and curl

Varidim and Curl Tester

- Impact of humidity on the dimensional stability of paper

- Characterisation of curl (principal direction and radius of curvature)

- Testing according to standards ISO 8226 and ISO 11556

General informations

Plant fibres, which are the main raw material used in paper, are hydrophilic, i.e. they absorb or release water depending on the ambient air humidity. This results in a swelling or thinning of the fibres and, by transmission to the entire fibre network, in dimensional variations in the paper.These dimensional variations can occur in the sheet plane and lead to register or floating edge problems for printers.

They may also not be identical on the 2 faces of the sheet and result in curl, which will be detrimental to machinability and stacking quality.

The CTP is equipped with the resources required to measure the tendency of papers to vary in dimensions and/or to curl during variations in humidity.

Technical Data and Achievements

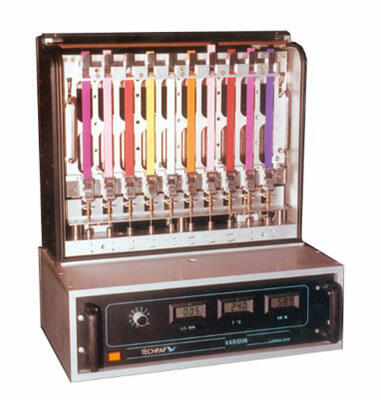

Varidim apparatus

Measurement principle

Test pieces take the form of strips of paper held by magnetised clamps. They are placed in a humidity-controlled chamber. Variations in humidity lead to variations in the length of the test piece (expansion and shrinkage) that are recorded by displacement sensors.

Technical data:

Programmable humidity level between 15% and 90% RH

Clamps calibrated depending on paper grammage

Possibility of determining the Young’s modulus by adding an instantaneous load.

Duration of test: from 4 to 24 hours

Possibility of testing up to 10 strips simultaneously

- Variations in dimensions according to standards ISO 8226-1 and ISO 8226-2, or at various levels of increasing or decreasing humidity between 20% RH and 80% RH at 23°C on a Varidim apparatus.

Also available at the CTP:

- Measurement of dimensional change after immersion in water, according to the standard ISO 5635 or standard NF Q 03-063

Curl Tester apparatus

Measurement principle

The test piece takes the form of a disk of paper held vertically and placed in a humidity-controlled chamber. The variations in humidity will cause the test piece to curl.

The apparatus automatically detects the angle of curl and determines its amplitude over the course of the humidity cycles.

Technical data:

Programmable humidity level between 15% and 90% RH

Test duration: from 15 mins to 24 hours

Only one test piece can be tested at a time

- pended test piece, according to the standard ISO 11556

Also available at the CTP:

- Curl in various atmospheric conditions, according to the method described in the “Poster” standard (withdrawn standard)

Curl in a pack of sheets, according to the standard ISO 14968

|

|

|

| Varidim | Curl |