Services

Testing Laboratory

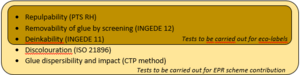

Graphic printed products : recyclability tests

Repulpability - Deinkability- Glue behavior – Discolouration

- Check that the fibres are repulpable (individualisation of fibres)

- Determine the behaviour of adhesives and their impact on the paper-making process

- Determine the behaviour of inks during deinking by flotation

- Determine the possibility of discolouration of dye-based inks or mass-dyed papers

General informations

One of the ways in which graphic printed products (newspapers, magazines, leaflets, etc.) can be recycled, also known as deinking. This involves :

- Individualising the fibres (repulpability test)

- Limiting the impact of tacky particules known as ‘stickies’ (a source of optical defects, fouling on paper machines and even breakage on them or during the conversion of the paper produced)

- To eliminate ink particles or decolourise the dyes present in order to re-establish a sufficient level of brightness so that the deinked pulp obtained can be used to manufacture new graphic papers.

Technical Data and Achievements

The various tests

Repulpability

In the case of wet strength treated papers, good repulpability is validated using the PTS RH test, which involves pulping stage at high consistency with deinking liquor. The level of individualisation of the fibres is checked following Somerville screening. The quantity collected on the screens must be less than 5% for the paper to be declared repulpable.

Potential for eliminating glues by screening

Such tests are carried out following the protocol defined by the INGEDE method 12, in which the adhesive particles are revealed and quantified. Based on these parameters, an adhesive elimination potential score is calculated according to the scheme defined by the EPRC (European Recovered Paper Council). A score above 71 pts corresponds to an adhesive application with good elimination potential.

Glue redispersibility and its impact on the papermaking process

Firstly, it is checked that the application of the potentially waterdispersible adhesive is actually water-dispersible: the adhesive must not lead to macrostickies (determined using the INGEDE method 12) and the dispersibility rate measured via the dissolved

and colloidal substances released must be greater than 85%. If this is the case, the additional quantity of dissolved and colloidal matter is assessed via the chemical oxygen demand (COD) and cationic demand. The risks of uncontrolled agglomeration of these substances are assessed (agglomeration under the effect of shear and in the presence of calcium ion) as well as the possibility of controlling these colloids via a coagulation test. An adhesive is then considered to be water-dispersible if the dispersion rate reaches 85% and the impact score is greater than 80%.

and colloidal substances released must be greater than 85%. If this is the case, the additional quantity of dissolved and colloidal matter is assessed via the chemical oxygen demand (COD) and cationic demand. The risks of uncontrolled agglomeration of these substances are assessed (agglomeration under the effect of shear and in the presence of calcium ion) as well as the possibility of controlling these colloids via a coagulation test. An adhesive is then considered to be water-dispersible if the dispersion rate reaches 85% and the impact score is greater than 80%.

Deinkability

A deinkability test by flotation is carried out using the INGEDE method 11, which looks at luminosity, red/green shade and the quantity of ink particles larger than 50μm, as well as process parameters such as the ink elimination index and the colour of the process water. Based on these parameters, a deinkability score can be calculated according to the scheme defined by the EPRC (European Recovered Paper Council). A score higher than 71 pts corresponds to a printed product with good deinkability. Note that for some printing technologies, this score is only valid for the paper/ink combination tested.

Discoloration

Dye-based inks as well as dyes used for mass-dyed papers, cannot be removed by a flotation step, even though they can have a significant impact on the brightness of the pulp. However, decolourisation tests simulating hydrogen peroxide bleaching and hydrosulphite bleaching can be carried out to demonstrate that the dyes used are potentially decolourisable. The corresponding test is carried out in accordance with the ISO 21896 standard.

Also to be seen

Centre of Excellence

Testing Laboratory

home.label.liaison.www_webinaire