Packaging: Recyclability test

Repulpability - screening - hydrocycloning - efficiency – extraction rate

- Verifying packaging recyclability as defined by the standard EN13430: recovery through recycling of material

> Determining composition (paper-cardboard: primary material) to ensure recycling is possible within the papermaking industry

> Verifying suitability for repulpability, removal of unwanted materials and the quality of the final pulp - Determining the percentage recyclable of the packaging and the paper-cardboard fraction extraction rate

General informations

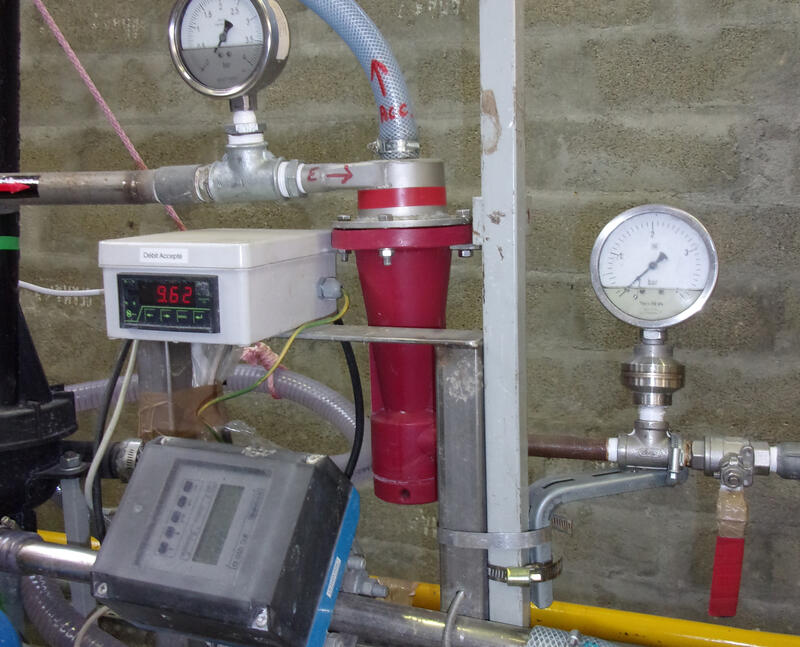

Laboratory equipment (pulper, screen, hydrocyclone and handsheet former is used to determine whether a packaging product is compliant with packaging directive 2018/852/EU regarding recovery through recycling (EN 13430).

Three main product types are tested:

- finished packaging, already released onto the market

- packaging that is currently undergoing development or intermediate products

- components used in the composition of the packaging.

The CTP is a reference in its field and has carried out more than 650 recyclability tests.

It is currently the only centre to offer the stage of hy-drocycloning for heavy particles as part of the recyclability test, which eliminates any residual particles that remain after the screening stage.

These studies are carried out by personnel with 15 years of expertise in the field of waste sorting, eco-design and recycling.

Technical Data and Achievements

Packaging directive 2018/852/EU

Marketed packaging must comply with the European Directive 2018/852/EU (Packaging and Packaging Waste) and its counterpart in French law (French Environmental Code, decree 2014-1467).

It must be possible for packaging as defined in European Directive 2013/2/EU to be recovered at end-of-life using the classification system outlined in European Directive 2018/851/EU (article 4). Paper and cardboard packaging that is difficult to reuse directly (EN 13429), must preferentially be sent to materials recycling channels (EN 13430): in this case the recyclability of the packaging needs to be checked.

Verifying product recyclability as defined in the EN13430 standard involves validating two criteria:

- Mass composition of the packaging

The packaging must consist of at least 50% paper-cardboard by weight, which is checked on the basis of the manufacturing data sheet provided with the product (or additional analyses made prior to the recyclability test). - Suitability for recycling

- Defibering or repulpability: verifying that the product disintegrates and the fibres disperse by visual observation

- Elimination of unwanted materials

- Triple screening stage (holes 5 mm, slots 15/100 & 10/100 mm) to check for the presence of fibre bundles / flakes, total removal of lamination films, etc…

- Hydrocycloning stage for heavy particles after screening (if necessary),

- Determination of the percentage recyclable for the packaging and the paper-cardboard fraction extraction rate - Final quality of the pulps and papers produced:

Manufacturing of laboratory handsheet for assessing:

- the visual aspect of the manufactured papers

- the presence of tacky particles (adhesion test).

Study results and outcomes

- Approval of the composition for the first recyclability criterion

- Quantitative determination of screening rejects in accordance with the manufacturing data sheet

- Verification of the quality of the final pulp and assessment of the visual appearance of the manufactured handsheet

- Determination of the percentage recyclable of the packaging and of the paper-cardboard fraction extraction rate

- Conclusion: decision on whether the product is recyclable or not

Specific aspects of CTP expertise

- Hydrocycloning for heavyweight particles

- Calculation of fibre losses

- Recommendations for improving product recyclability/eco-design

- Reuse channel

|

|

|

| Triple screening step (Somerville devices) | Heavyweight cleaning step |