SpotView (2016-2020)

Sustainable Processes and Optimized Technologies for Industrially Efficient Water Usage

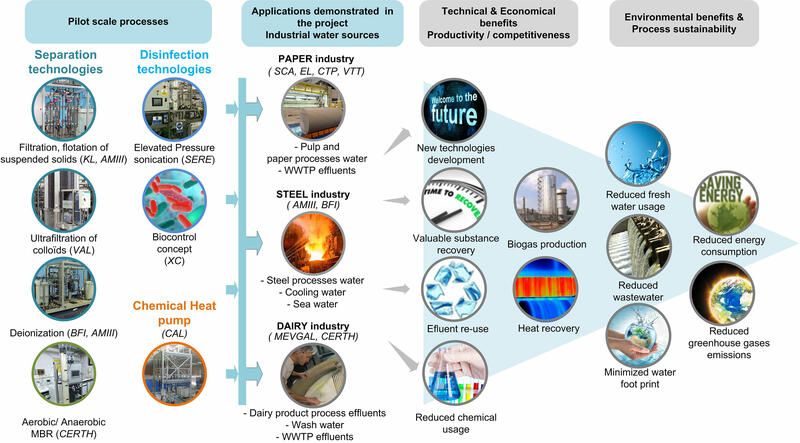

The 3 main objectives of the SPOTVIEW project were:

- to develop and demonstrate innovative, sustainable and efficient techniques,

- to optimize the use of natural resources, especially water, in three industrial sectors (Dairy, Pulp and Paper and Steel),

- to assess a total of 14 existing and new separation and treatment technologies at pilot scale.

Aim of the project

In Europe, manufacturing industries contribute to 12% of total water withdrawal. The three industrial sectors involved in the project account for 44% of industrial water usage in EU, including cleaning, diluting, transporting or cooling, as well as steam production for heating, drying or disinfecting. In a context of increasing water scarcity, process industries have to reduce their dependence to fresh water resources, by adopting new solutions for process water and effluent treatment and reuse. This resource optimization (including water, energy, raw materials and additives) is a key issue to maintain production competitiveness and sustainability. The SpotView project developed in this global warming context allowed significant breakthrough to emerge.

Initial SpotView objectives were:

- To develop and demonstrate innovative, sustainable and efficient processes and technologies, to optimize water usage in the three industrial sectors

- To assess 14 existing and new technologies, including solid/liquid separation, ultrafiltration, deionization, biological treatment, disinfection and chemical heat pump

- To combine technologies components for assessment in simulated or operational environment for 9 new water management practices

- To evaluate processes and technologies implementation in terms of environmental impacts and benefits, generated by achieving the SPOTVIEW targets (20% to 90% reduction of water usage, wastewater emissions, chemicals and energy use)

Main SpotView results for Paper Industry:

- Modelling of effluent recycling scenario with heat recovery integration showed potential reduction of fresh water uptake from 20 to 50% with efficient control on process water COD, temperature and conductivity

- Valmet Ultrafiltration CR1010/30T prototype installed in tissue mill showed effective process water purification and fresh water saving by 1-2 m3/ton

- BioControl concept producing sodium hypochlorite from process water requires preliminary brine concentration with nanofiltration or reverse osmosis to be applied in tissue paper mill

- A patented technique developed for starch extraction from recovered paper and board recycling processes needs to be improved for industrial exploitation

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 723577.