Abrasion - Abrasiveness - Friction

Quality control and tests on papers and boards

- Abrasiveness testing on abrasive and non-abrasive papers, transportation separators, bottle packaging

- Abrasion resistance according to standard NF Q 03-055

- Static and/or kinetic coefficients of friction according to the standards NF Q 03-083 (inclined plane), NF Q 03-082 and ISO 15359

- Ink resistance according to the standard NF Q 03-072

General informations

Surface properties such as smoothness or roughness can be characterised using the equipment at the Physical Properties Testing Laboratory.

Abrasiveness, resistance to abrasion and friction coefficients can also be measured.

The main product groups addressed in order to characterise the behaviour of a material in contact with itself or with another material, are:

- raw materials such as paper, tissue paper, folding boxboard, corrugated board, composites, etc.

- finished products such as cardboard boxes, folding cartons, bricks, books, brochures, tissue products, blister packaging, labels, etc.

These tests can be implemented after standardised conditioning or after heat-, moisture- or cold-ageing.

Technical Data and Achievements

Abrasiveness and abrasion resistance

These tests are performed when the objective is to evaluate the loss of material caused when a material being tested (paper or board) is rubbed against another material. This second material can also be a paper/board, or a plastic or metal surface.

- When the paper or board being tested damages the surface it is rubbed against, the paper/board is said to be abrasive.

- When the paper or board being tested loses matter, its abrasion resistance is measured.

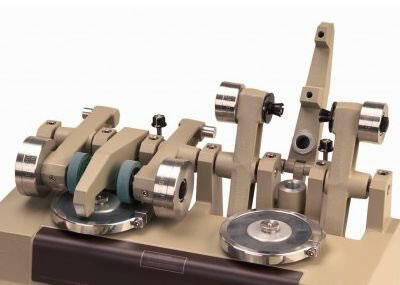

These tests can be performed on two different devices, known as usometers, which put the surface being tested in contact and in motion with respect to another surface:

- Taber usometer: the abrasion resistance measurements can be performed according to the standard NF Q 03-055 by rubbing the material to be tested against calibrated grinding wheels (sandpaper of varying coarseness) and measuring loss of the tested material in terms of mass

- Lhomargy usometer: this device is generally used to evaluate the abrasion resistance of printed substrates and the evaluation is carried out visually or by optical density measurement.

Coefficient of friction

These tests are performed in order to characterise the force required to initiate and/or maintain uniformity of movement between two surfaces. The surface being tested (paper or board) can be put into contact with itself or with another material (glass, rubber, etc).

The tests can be performed in accordance with the following standards:

- Coefficient of static friction TNO, according to standard NF Q 03-083, inclined plane method

- Static and kinetic coefficients of friction, on an Instron DY35 dynamometer, according to standard NF Q 03-082 or ISO 15359.

Abrasion resistance

The tests performed on the Crockmeter device provide a means of evaluating the change in colour of a sample subjected to back-and-forth rubbing. The material being tested (generally coloured or printed) is rubbed with a pad covered in a white fabric. After a certain number of back-and-forth movements, the coloration of the fabric is measured. If the sample material is white or light-coloured, a dark cloth is used.

The tests can be carried out:

- In dry or wet conditions (in the latter case, the material to be tested is wetted before the test)

- In accordance with the standard NF Q 03-072.

|

|

|

| Taber usometer | TNO friction |