CelluWiz (2019-2022)

Process developments to obtain 100% cellulosic packaging material, barrier, recyclable and compostable

Aim of the project

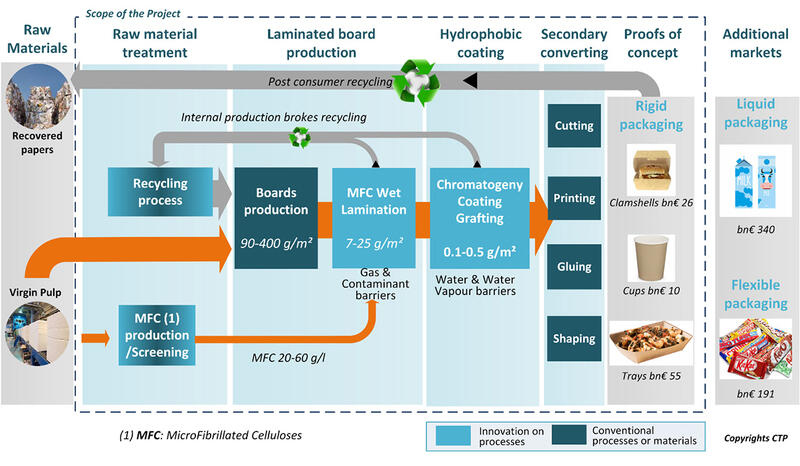

Celluwiz is a research project funded by the Bio-based Industries Joint Undertaking, a public-private partnership with the European Union (H2020 programme) and the Bio-based Industries Consortium. The project has 4 objectives :- Develop the wet lamination process of a Microfibrillated Cellulose (MFC) layer on a paper/cardboard at the pilot scale (TRL5). This process allows assembling a layer of MFC and a board without the use of glue. The MFC layer brings barrier properties to the grease, the contaminants and oxygen to the material.

- Develop a chromatogeny process adapted to MFC layers (TRL5). This rapid and solvent free process allows modifying the extreme surface of the cellulose in order to confer water and water vapor barrier properties without damaging the recyclability.

- Produce 3 proof-of-concept 100% cellulosic, barrier, recyclable and compostable: clamshell, cup and tray.

- Demonstrate the environmental and economic benefit of the developed solutions.

The CelluWiz project takes part in this challenge by developing two innovative processes to produce all cellulosic multilayer packaging which are recyclable and compostable and which present barrier properties required for food packaging.

CelluWiz is a multidisciplinary project coordinated by the CTP, which regroup 5 partners from 4 European coun-tries. 2 of these partners are major industrial groups – Stora Enso and Voith, and the 3 other partners are research organizations - the CTP, ITENE and the CNRS. Moreover, an advisory group composed of industrials from food and machine manufacturing as well as associations has been created to contribute to the project development and guarantee its relevance compared to the expectations and constraints of the entire value chain.