Microscopic analyses of lignocellulosic materials

To characterize the fibres for enhancing the products

- To determine the fibrous composition and recognise the origin of the fibres

- To visualise and understand the impact of processes on the structure of fibres and materials

- To analyse and localise the mineral components present in the lignocellulosic materials

Generate Value...

CTP has acquired an expertise in the structural characterisation of lignocellulosic materials and their components since many years. It has developed methods in optical microscopy, scanning and transmission electron microscopy to understand the impact of mechanical and/or chemical treatments on the morphological characteristics of materials (pulping, refining, sheet forming, coating, finishing, etc.).

With more than hundred analyses per year, CTP has helped the industrialists to understand the origin and solve some defaults of production. Moreover, these analyses allow verifying the conformity of products towards specifications of production and use. Therefore, solving of litigations has allowed the manufacturers some substantial savings and to prove the conformity of their products.

Fibrous composition : 60% mechanical pulp – 40% chemical pulps (Herzberg reagent)

Context and performance

The characterisation of fibres from lignocellulosic materials is of major importance in the understanding of processes of production and converting, such as in the analysis of the final product.

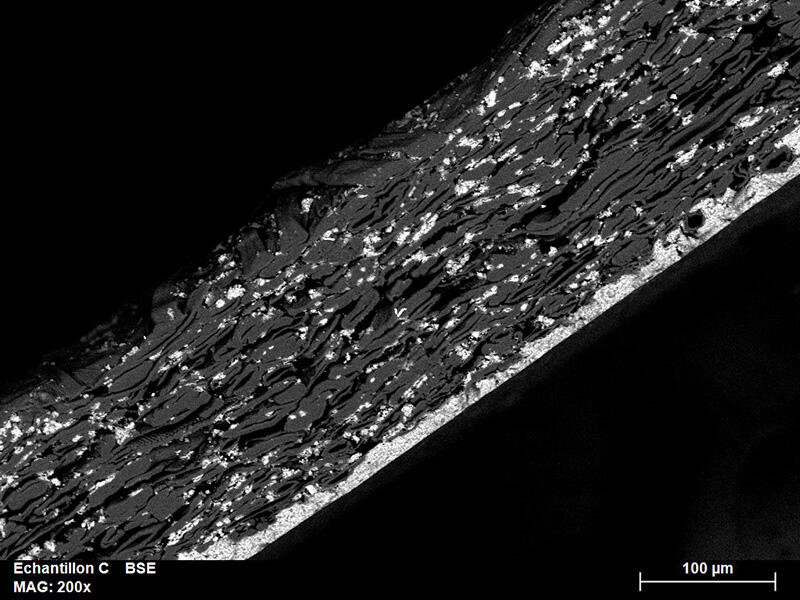

CTP identifies the fibrous composition of your material, determines the origin of fibres and analyses the production and converting defaults by the way of optical and scanning electron microscopy (SEM). The SEM associated to a photon X detector enables determining the chemical nature of the mineral components used in the production of the materials, on the surface or in its thickness, and to map them.

Some components of the lignocellulosic fibre walls can be localise by using specific antibodies against these components (immunolabelling) associated to optical or transmission electron microscopy to optimise the different treatments applied to the fibres during their production.

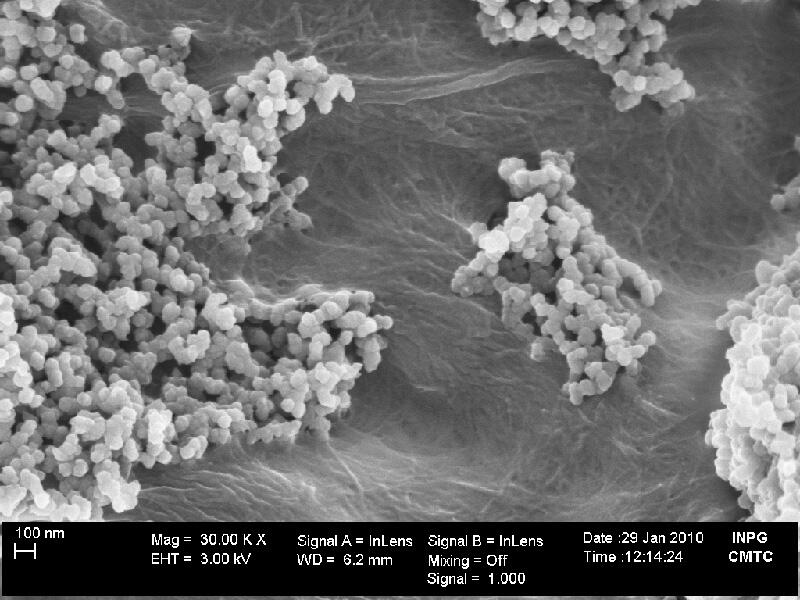

The CTP expertise in high-resolution microscopy allows also analysing the new additives of papers and boards, such as microfibrillated cellulose, nanoparticles, etc.

Distribution of mineral fillers in the paper thickness (SEM)

Content of services

Depending on the objective of the analysis, CTP carries out the following services:

- Fibrous composition (ISO 9184) associated to the recognition of fibres (processes and species).

- Determination of the number of vessels for the hardwood species

- Microscopic examination of defaults, of distribution of fillers at the surface or in the thickness of the material structure, etc

- X-ray microanalysis for mineral components and the associated localisation map

- Immunolabelling of fibre wall components.

Examination of nanoparticles at the surface of a microfibrillated cellulose film (SEM)

Deliverables

CTP supplies an analysis report indicating:

- the data, resulting from the analysis

- some microphotographs to illustrate the obtained results

- some eventual recommendations, depending on the object of the demand.