Production of refiner mechanical pulps

To simulate the processes for reducing production costs and environmental impact

- To evaluate new raw materials or biomasses mixtures or pre-treatments facilitating mechanical pulping

- To optimise the conditons of pulps manufacture

- To compare different pulping and bleaching processes for a given biomass

Generate Value...

Since the early 1990s, CTP has proposed to industrialists its expertise in the manufacture of refiner mechanical pulps (RMP, TMP, CTMP, APP) to decrease the energy consumption and to improve the pulp quality by simulating the process at pilot scale with new raw materials, biomasses mixtures, specific pre-treatments (mechanical and/or chemical and/or enzymatic) and with new operating conditions (temperature, pressure, time, refining intensity…).

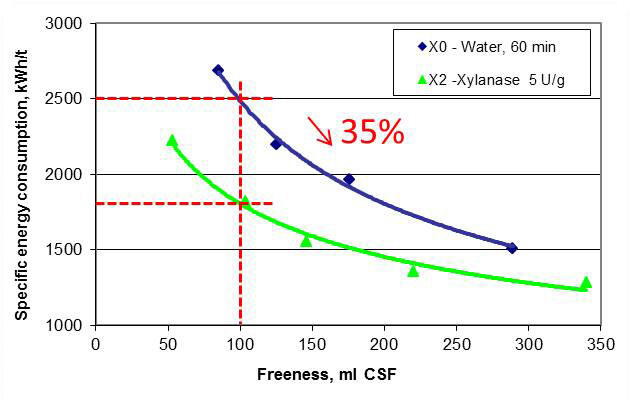

By the way of research projects dedicated to pretreatments of raw materials (chips compression, enzymes, ozone…), energy savings from 10 to 30% were obtained for a comparable pulp quality and can be transferred to the industry.

All the produced mechanical pulps can be bleached at laboratory or pilot scale in the conditions as comparable as these used at industrial scale.

High yield pulping process

Context and performance

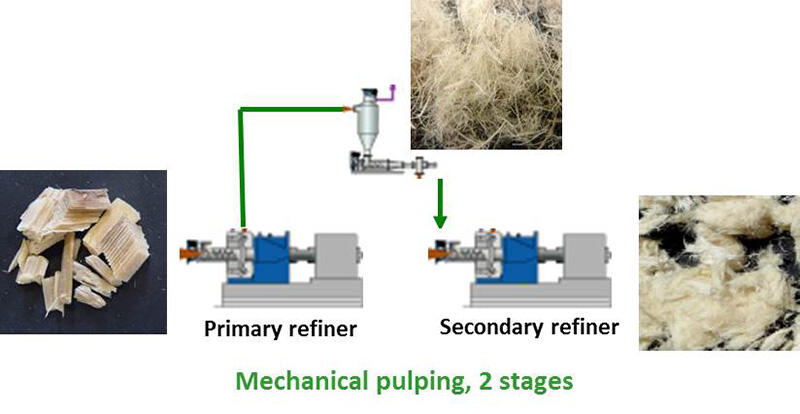

20% of the world pulp production are mechanical pulps. CTP is equipped with a pilot plant allowing simulating the main refiner mechanical pulping processes: RMP, TMP, CTMP and APP, because it is not possible to simulate them at laboratory scale.

From our raw materials and your industrial conditions, it evaluates the impact of changes in operating conditions, the introduction of a pre-treatment or the use of other lignocellulosic resources on the energy consumption and on the pulp quality. This production can be completed by bleaching in one or two stages with different bleaching chemicals.

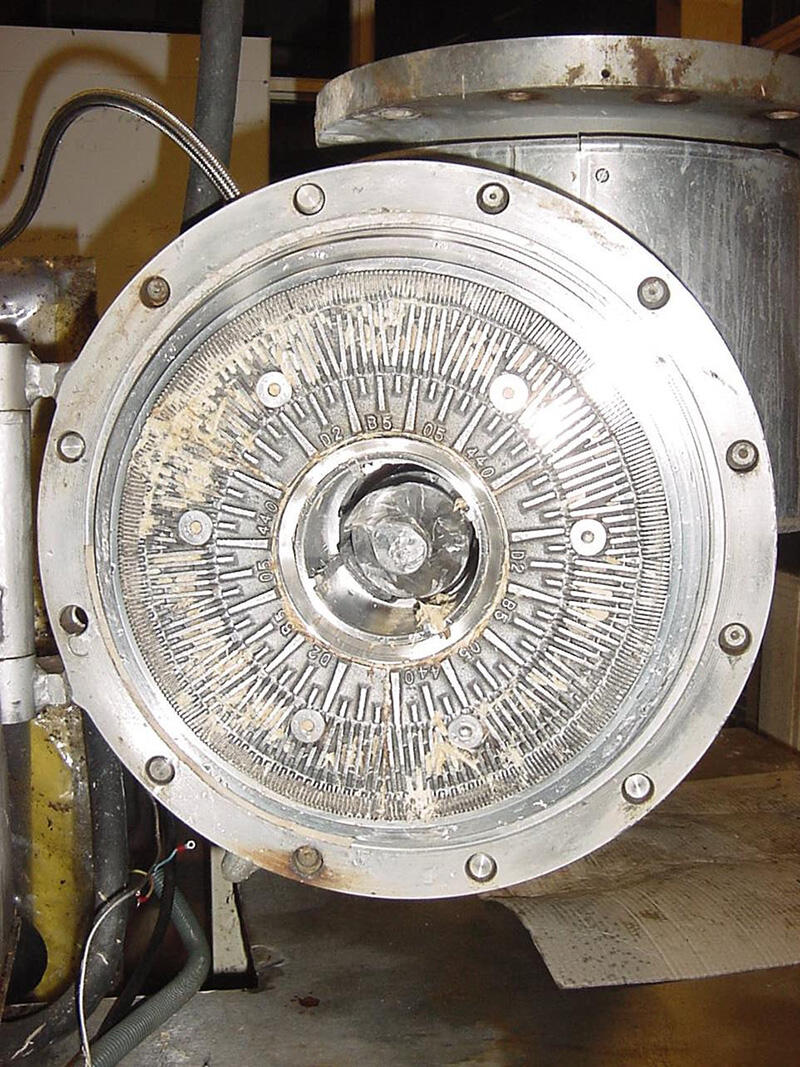

Defibering refiner discs – Opened refiner

Content of services

Depending on the objective of the study, CTP can perform:

- Mechanical pre-treatment of the raw material with a MSD Pressafiner

- Chemical pre-treatment of the raw material combined or not with a mechanical treatment

- Enzymatic pre-treatment of the raw material combined with a mechanical treatment

- Defibering of the chips with different intensities at atmospheric pressure or under pressure

- Refining of the primary refined pulp at atmospheric pressure or under pressure to obtain a refining curve

- Bleaching at medium or high consistency with sodium dithionite or alkaline hydrogen peroxide

- Accelerated ageing by UV irradiation (Suntest)

- Evaluation of the quality of pulps and fibres

Impact of enzymatic treatment on the energy consumption for mechanical pulping (TMP)

Deliverables

CTP will supply a study report indicating the specific energy for producing the pulp, the refining curve, the bleachability of the pulp and the photo-yellowing behaviour, the pulping yield, the pulp quality, the process environmental impact, the comparison of the different studied conditions and some recommendations with evaluation of the potential savings.