Energy performance

Reducing costs while managing energy consumption

- Carry out energy performance studies for your processes and equipment

- Analyse thermal and electrical energy consumption

- Make technical recommendations and profitability forecasts

- Draw up an action plan to reduce your energy consumption

Generate Value...

Controlling energy costs and CO2 emissions is a major environmental and social concern for the papermaking industry, in order to contribute to reducing the impact of climate change.

The CTP has been helping papermakers to improve their energy performance for many years.

It has more than 30 years of experience in expert appraisals of drying sections and has performed many audits of electricity consumption involving pulping, refining, vacuum systems, pumping, compressed air, etc.

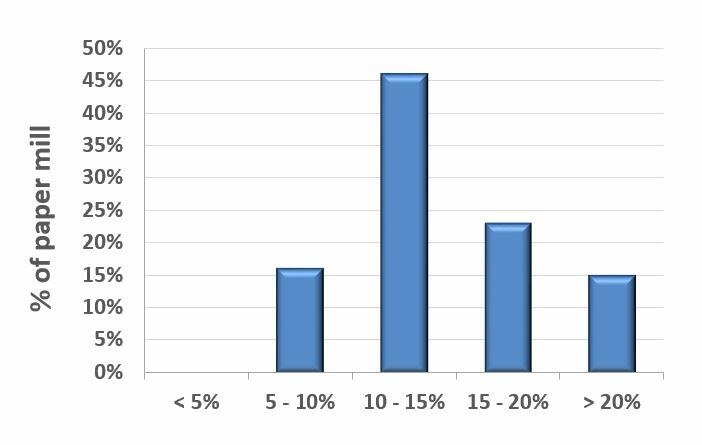

Studies of more than 200 drying sections have been completed with potential gains frequently reaching 10% of thermal consumption. Potential energy savings can be as high as 10% of the electricity bill for a site, with related annual savings amounting to several hundreds of thousands of euros.

Context and performance

The energy bill of a paper mill represents 10% to 30% of its annual production costs. It is made up of thermal costs and electrical costs. The CTP draws up in-depth energy balances and proposes actions to reduce your fuel, steam and electricity consumption. It also performs specific studies on processes and equipment identified by players in the industry having implemented an energy management system (ISO 50001 or other).

Content of services

Our proposals are designed to meet your specific requirements. In general, our approach consists firstly in drawing up overall performance indicators and comparing them with reference values in order to determine potential energy savings. Secondly, a more detailed study of the processes and equipment that use the most energy is performed. This study makes use in particular of measurements made on site.

The study can involve:

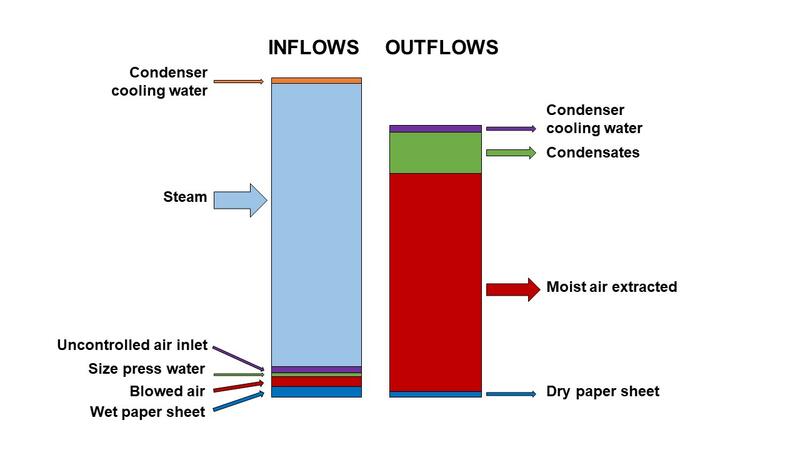

- A full assessment of drying sections (single- or multi-cylinder) and coaters

- A study of the possibilities for heat recovery

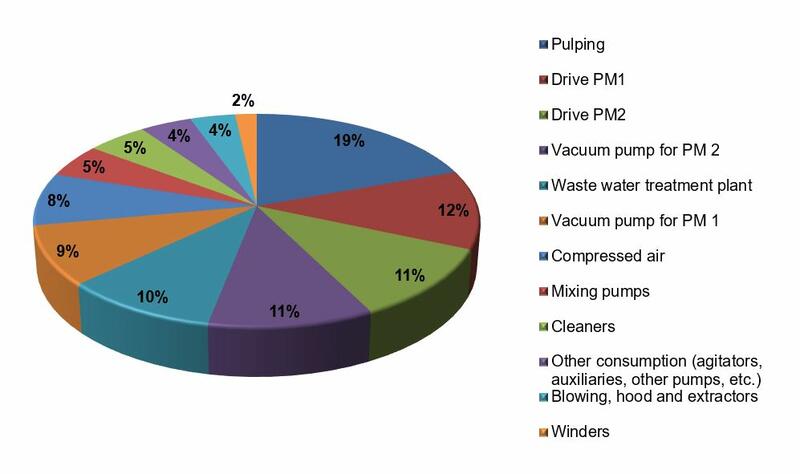

- An assessment of electricity consumer items (vacuum system, refining, pulping, compressed air, pumping, ventilation, etc.)

Measurement of electricity consumption / Distribution board

Delivrables

The CTP provides an energy audit report specifying:

- The levels of energy consumption on an overall basis and per energy consumers.

- Deviation from reference values and the ideal situation.

- Recommendations for improvements, with an estimate of potential energy saved, the investments required, economic cost/benefit considerations and highlighting the greenhouse gas emissions that have been avoided.