Audit of industrial units of lignocellulosic fibres refining

To optimise the refining of fibres to save electrical energy

- To analyse the running, the control and the efficiency of refining lines

- To propose solutions to save energy and to increase the potential of development of used fibres

- To reproduce with a pilot scale simulation bench the refining conditions and to optimise them, depending on fibres, targeted properties and on equipment available or scheduled

Generate Value...

Refining of lignocellulosic fibres is a key step in the preparation of fibres for the manufacture of papers and boards to enhance the mechanical properties of the fibrous web.

The evolution of fibrous resources, towards short fibres, of equipment and/or staff needs some adaptations in order to guarantee the best efficiency of this high-consuming energy process step.

By the analysis of each refiner and of the fibres, it is possible to propose modifications generating substantial energy savings. In some cases, pilot trials allow an advanced optimisation and the proposal of original solutions to generate supplementary savings.

A decrease of production costs from 5% to 40% are envisaged, depending on fibres and considered levels of refining.

Low consistency refining pilot

Context and performance

The refining unit of paper mills is an important post of energy consumption, of maintenance and of consumables (refining plates).

CTP can carry out some in-depth audit of the refining unit to estimate the potential energy savings and the efficiency of each refiner composing the line. Through pulp sampling before and after each refiner and refiner running control data, a balance-sheet of refining line running is drawn up, allowing determining the enhancement possibilities.

In some cases, the simulation on CTP’s pilots, reproducing the industrial conditions in the mill with wider running possibilities than industrial units, allows testing original solutions. New plate patterns or treatments of fibres suspensions can be considered for reaching the targeted pulp quality. Thus it will be possible to produce a paper sheet answering the mill specifications with the right necessary energy requirement.

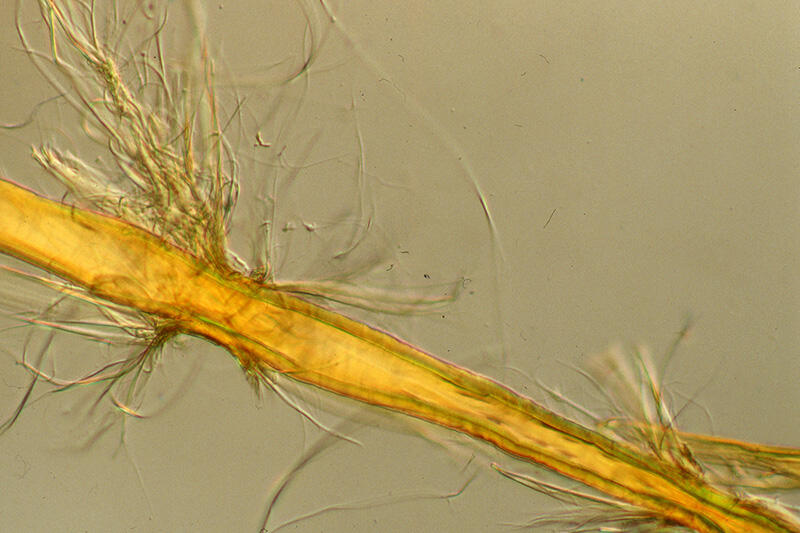

External fibrillation of a fibre after refining

Content of services

The content of this audit can integrate:

- A complete balance-sheet of refining unit running

- An in-depth analysis of the impact of each refiner on fibres characteristics and on the main optical and mechanical properties of the pulp

- A simulation at pilot scale to optimise the refining conditions for each fibre grade

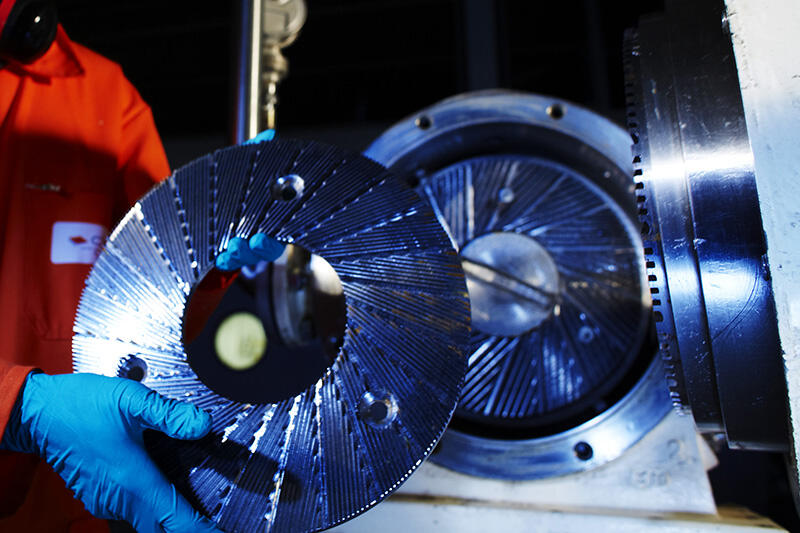

Refiner discs used for refining the fibres at pilot scale

Deliverables

CTP will supply a study report composed for the main considered steps of:

- The today situation, including the efficiency of each refiner and of the complete line on the modifications of fibres characteristics and of pulp properties

- Optimised running conditions of the refining line

- Some proposals of line running and/or investment associated with an evaluation of the potential energy savings