Producing bio-based materials by reactive extrusion

Extraction of fibres, molecules and production of MFCs by twin-screw extrusion

- Extract fibres from lignocellulosic materials for the production of paper/cardboard or 2D or 3D biobased materials

- Extract molecules of interest and added value from lignocellulosic materials for various markets

- Produce high-concentration microfibrillated cellulose (MFC) by combining chemical, enzymatic and/or mechanical treatments

Generate Value...

In the 1980s, the CTP developed a reactive extrusion technology using a twin-screw extruder to produce paper fibres from wood chips and annual plants, leading to industrial applications in several countries.

Today, in the context of the bioeconomy, this technology is regaining interest as a means of extracting value-added molecules and adding value to compounds such as lignin and hemicelluloses.

With the support from the AuRA region, the CTP installed a new twin screw extruder in 2019, patenting with LGP2 an innovative method for producing microfibrillated cellulose with low energy consumtion.

This technology is also promising for the manufacture of foams based on lignocellulosic fibres.

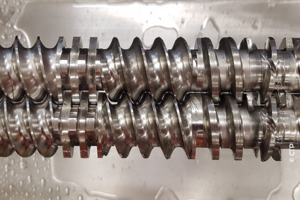

Twin screw extruder with rotating co-penetrating screws

Context and performance

For many years, the CTP has been studying twin-screw extrusion technology for the production of paper fibres. The acquisition of a twin-screw rotary co-penetrating extruder has made it possible to produce demonstrators and validate new concepts for extracting fibres and molecules, and producing mechanical or chemical pulps and high-concentration MFCs using reactive extrusion.

Food contact symbol

Production of paper fibres

Production of paper fibres

Content of services

Depending on the purpose of the tests, the CTP can carry out :

- Simulations and optimisation of rotary co-penetrating screw shear profiles adapted to the fibre raw material, the desired pulp and MFC quality and the desired energy consumption,

- Fibre extraction from various lignocellulosic materials using a combination of chemical, enzymatic and/or mechanical treatments,

- Production of microfibrillated cellulose from different lignocellulosic fibres using patented technology,

- The extraction of molecules of interest from different lignocellulosic materials,

- The manufacture of lignocellulosic foams using different raw materials and additives,

- Reactive extrusion trials with different materials, including bio-based polymers, or any other trial based on reactive extrusion..

Production of high-concentration MFC

Deliverables

The CTP will provide a test report including the conditions used, the energy consumed and the analyses carried out on the samples produced. The CTP will also deliver the batches produced for external analysis or for specific use tests at the customer’s premises.