ULTRACELL (2018-2020)

Ultrasonic welding of paper and nanocellulose

Development of an ultrasonic paper and board welding process making it possible to :

- eliminate glue and the associated food contact problems for paper and board packaging,

- guarantee a sharp reduction in the costs related to packaging recycling, and the absence of mineral oils or other contaminants,

- achieve performance levels comparable to those of adhesive-based assemblies in terms of adhesion quality, energy cost and production rate.

Aim of the project

Performed in collaboration with the 3SR laboratory, the LGP2 laboratory and the Sonimat company and coordinated by the CTP, the work consists in (i) determining the optimum process parameters by acquiring experimental data in situ and understanding the temperature increase phenomena; (ii) gaining an in-depth understanding of the adhesion development mechanisms by revealing the relationships between chemical compositions (papers, fibres and nanocrystalline cellulose) and peel performance; (iii) studying ways to improve adhesion by developing nanocrystalline cellulose (NCC) with suitable thermal and physical properties; (iv) and lastly, designing a welding demonstrator dedicated to assembling papers and boards and estimating the cost of the technology change and the saving achieved for existing glued or heat-sealed assemblies.

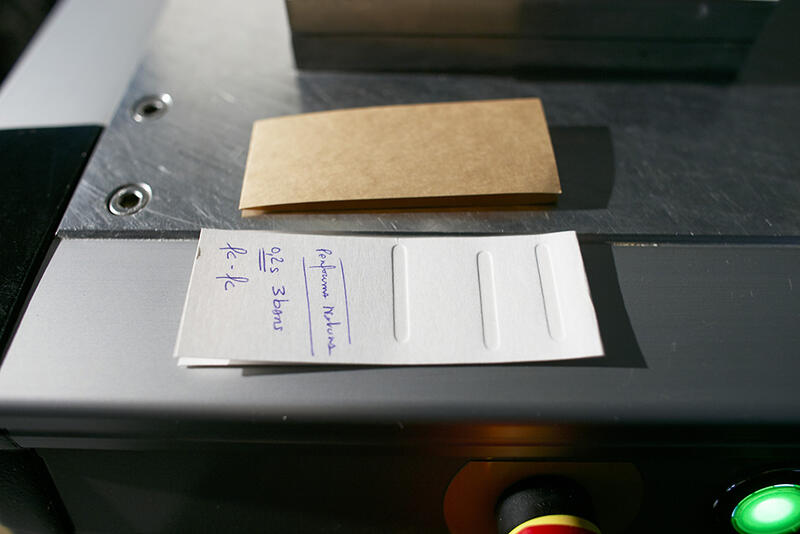

An instrumented welding device has been developed in order to be able to make the connection between energy delivered, energy absorbed, temperature increase and adhesion development.

Coated boards (with a pigment coating to ensure printability) demonstrate a degree of suitability for assembly using ultrasonic welding. The potential market is large (10 Mt/year in the EU), but the technology change would mean redesigning the folding and gluing operations.

It is also possible to take advantage of the additives included in the composition of certain industrial papers and boards in order to weld them. Here too, the potential market is substantial.

Lastly, the size of the cellulosic elements deposited on the surface has a significant impact on adhesion development. Nanocrystalline cellulose offers some potential.

|

|