Bleaching / Fibres Functionalization pilot

Simulate your processes to reduce costs and / or environmental impact

- to simulate in a reproducible and reliable way all the bleaching stages and the functionalization reactions of lignocellulosic fibres

- to validate the laboratory results before considering costly industrial trials

- to produce bleached or functionalized fibres in sufficient quantity to evaluate their uses (batch of 75 to 100 kg)

The little story of the pilot

Since the 1990s, the bleaching / functionalization pi-lot, unique in Europe, has enabled many pulp produ-cers to improve or validate their bleaching process in order to:

- reduce production costs,

- improve the quality of the effluents generated (COD, AOX),

- reduce water and energy consumption,

- and reduce production times.

The results obtained at this semi-industrial scale have been validated in mills producing up to 1 mil-lion tons of pulp per year.

Likewise, bleached pulp samples were produced before the start-up of new mills, in order to anticipate the marketing of future pulps.

Characteristics

Reproducible and reliable simulation of all bleaching stages and the functionalization reactions, whatever the conditions.

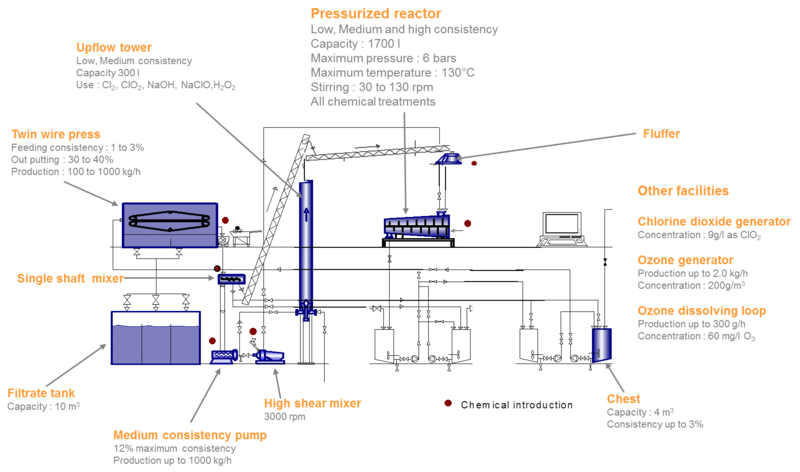

The reactions or bleaching stages are carried out in batch in such a way that after each stage, the pulp is sent to a tank, then diluted and washed on a doublewire press before a new stage. The process condition ranges on the pilot are as follows:

- Temperature: 25 to 100 ° C

- Fibre consistency: 5 to 20%

- Pressure: 0 to 5 ba

- Fibres grades: chemical, mechanical, de-inked pulps from wood (softwoods and hardwoods) and annual plants

- Bleaching stages: O, A, Z, D, E, Eop, Ep, P, Po, FAS, Y, X...

- Functionalization reactions with all types of chemicals compatible with the pilot.

Validatation of laboratory results before industrial trials

CTP has been helping pulp producers to optimize the bleaching processes for many years (improving the optical and mechanical properties of the pulp, reducing scale deposits and reducing the environmental impact and produc-tion costs). The pilot was used to validate laboratory results before industrial transfer for more than thirty factories from different continents.

Besides, in addition to this pilot, CTP also has laboratory reactors, simulating industrial processes and making it possible to bleach 40 g to a few kilograms of pulp.

Production of bleached and / or functionalized fibres in sufficient quantity to evaluate its uses (batch of 75 to 100 kg)

This tool is very flexible, based on different mixing devices, points of addition of liquid or gaseous chemicals and a reactor capable of operating under a wide range of process conditions. It was designed to test the results of research. The quantities produced allow it to be used on other semi-industrial pilots (refiner, paper machine, etc).

|