Structuring paper and cardboard materials

Stratification and modelling for optimised lignocellulosic materials

- Optimise the structure of your multi-layer paper and board with a view to improving your products

- Evaluate the potential of different fractions of unbleached, bleached or recycled pulps, fine and MFC elements, fillers and additives on the expected properties of your multilayer lignocellulosic products

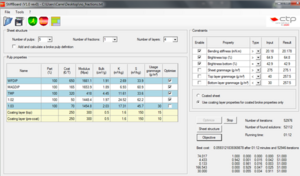

- Determine the optimum structure of the multi-layer lignocellulosic material at minimum cost using simulation software

Generate Value...

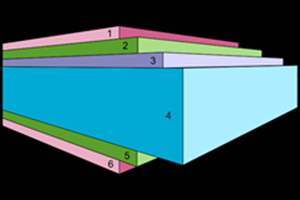

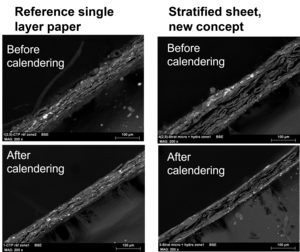

In 2015, the CTP patented an innovative technology combining the fractionation and stratification of layers of lignocellulosic material to lighten packaging while maintaining its rigidity. This approach makes it possible to optimise the technical properties of paper/cardboard by reducing the quantity of materials required, which would be impossible with a single material. Using simulation software, it is possible to design structures that meet the technical requirements at minimum cost. Widely used in flat and packaging board, this technology makes it possible to reduce grammage by 5 to 10%, resulting in savings of €4 to €8 per tonne while maintaining optimum performance !

Laminating multi-layer paper and cardboard

Context and performance

Drawing on its many years of R&D in paper-cardboard structuring, the CTP offers to optimise the structure of your multilayer paper-cardboards at minimum cost by simulating the grammage and thickness of each of the layers, studying the potential of different fractions of unbleached, bleached or recycled pulps, fine elements and MFC, fillers and additives to improve mechanical properties (flexural rigidity, tear & fold resistance, SCT & scott bond resistance), optical properties (luminance, whiteness, opacity, surface quality) and other properties (roughness, softness, permeability, barrier properties).

Difference between unlaminated and laminated paper in cross-section

Content of services

Depending on the purpose of the tests, the CTP can carry out :

- Simulate the optimum structure of multi-layer paper-cardboard at minimum cost, based on input data and possible constraints

- Fractionation of the fibres by hydrocyclone or classification according to the desired properties

- Appropriate treatment of each fraction to reduce energy consumption

- Redistribution of fractions throughout the thickness of the sheet

- In-depth characterisation of the mechanical, optical and other properties (roughness, softness, permeability, barrier properties) of the RK and/or dynamic formulations produced

- Specific development of properties according to specifications

Simulation software to define the optimum structure of multilayer paper-cardboard at lower cost

Deliverables

The CTP will provide a test report including the optimal structure of the multilayer material after simulation, the conditions used and the characterisation results.

The CTP will also be able to deliver batches of laminated sheets produced on request.